The food processing industry is a dynamic and demanding sector, constantly evolving to meet changing consumer demands for convenience, safety, and quality. From the initial sourcing of raw materials to the final packaging, efficiency is paramount. And at the heart of many food processing operations lies a critical, often overlooked component: the gear motor. Increasingly, food manufacturers are shifting their focus to a deep dive into gear motors and their applications performance optimization, recognizing that even small improvements in this area can yield significant returns in terms of productivity, cost savings, and adherence to stringent hygiene standards.

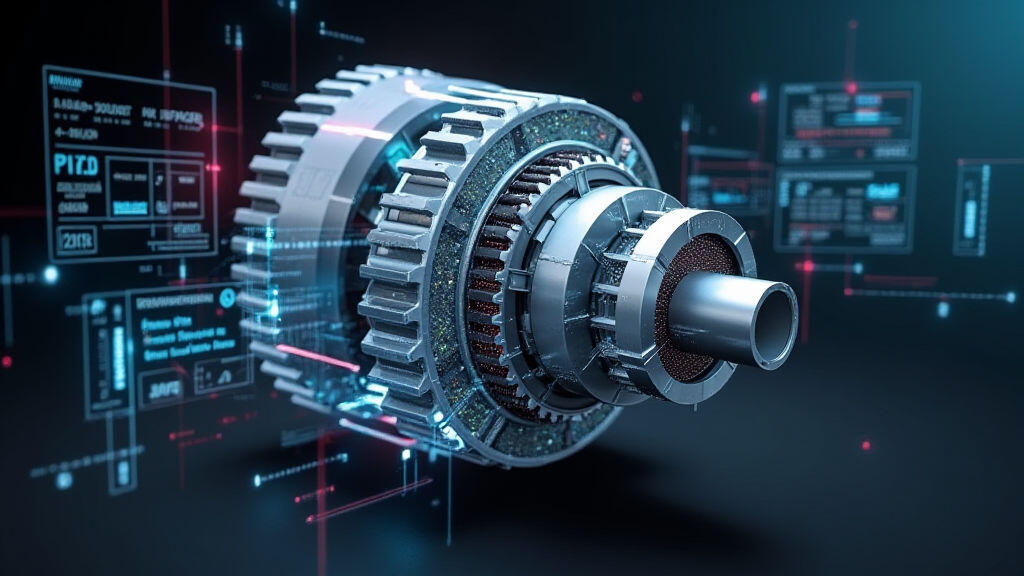

Gear motors are essentially electric motors coupled with a gearbox. This combination provides a powerful, controlled output with reduced speed and increased torque. In food processing, they are indispensable for a wide range of applications, including:

The food processing environment presents unique challenges for gear motors. Hygiene is, of course, the primary concern. Food manufacturers must comply with strict regulations like HACCP (Hazard Analysis and Critical Control Points) and GMP (Good Manufacturing Practices). Gear motors must be designed and maintained to prevent bacterial growth and facilitate thorough cleaning. This often necessitates the use of stainless steel components, sealed designs, and easy-to-disassemble features.

Beyond hygiene, reliability and efficiency are constantly being scrutinized. Downtime in food processing can be incredibly costly, leading to spoiled products, missed deadlines, and damage to brand reputation. Energy consumption is another significant cost driver. In today's environmentally conscious market, manufacturers are actively pursuing ways to minimize their carbon footprint.

Furthermore, the rise of automation and Industry 4.0 is placing even greater demands on gear motor performance. Sophisticated control systems require highly precise and responsive motors to ensure optimal operational efficiency and consistent product quality.

Manufacturers are adopting a multi-pronged approach to optimize gear motor performance in food processing:

MES-Drive is at the forefront of innovating gear motor technology for the food processing industry. They offer a comprehensive portfolio of high-performance gear motors, including those designed for hygienic applications and equipped with advanced features for condition monitoring and predictive maintenance.

MES-Drive’s solutions go beyond simply supplying gear motors. They offer:

The current trend in food processing is deeply intertwined with data analytics and Artificial Intelligence (AI). AI algorithms can analyze data from condition monitoring systems, predictive maintenance tools, and process sensors to identify patterns and predict potential failures with greater accuracy. This enables proactive maintenance, reducing downtime and optimizing performance. Furthermore, AI can be used to optimize motor control parameters, further improving energy efficiency.

The ongoing global discussion around food security and sustainability is also driving innovation in this field. Manufacturers are seeking ways to reduce energy consumption, minimize waste, and extend the lifespan of their equipment. Optimized gear motor performance plays a critical role in achieving these goals.

The increasing focus on gear motor performance optimization in food processing is not merely a trend – it's a necessity. By investing in advanced technology, proactive maintenance strategies, and specialized solutions, food manufacturers can achieve significant gains in productivity, cost savings, and regulatory compliance. The convergence of hygiene requirements, efficiency demands, and the rise of Industry 4.0, coupled with AI-driven predictive maintenance, underscores the critical role of gear motors in the future of food processing. As the industry continues to evolve, MES-Drive and other innovative companies are poised to play a key role in enabling food manufacturers to thrive in a competitive and increasingly demanding market. The ability to precisely monitor, predict and optimize gear motor performance will be a key differentiator for success in the years to come.

Leave A Reply

Your email address will not be published. Required fiels are marked